Project Information

SWG Schraubenwerk Gaisbach GmbH Produktion

DI Christoph Dünser

DI Mathias Schädler

DI Thomas Fußenegger

Hanna Bayer B.A.

Ing. Benjamin Baumgartl

Martin Rümmele

GAPP | Groß Architekten GmbH, München / Jan Leo Archut, Peter Lingenfelser

BHM Ingenieure & Consulting GmbH, Feldkirch

Mahl Projektsteuerung, Schwäbisch Hall

SWG Engineering, Rülzheim

BHM-Ingenieure Engineering & Consulting GmbH, Feldkirch

Rw-Bauphysik Ingenieurgesellschaft mbH & Co. KG, Schwäbusch Hall

BHM-Ingenieure Engineering & Consulting GmbH, Feldkirch

BHM-Ingenieure Engineering & Consulting GmbH, Feldkirch

BHM-Ingenieure Engineering & Consulting GmbH, Feldkirch

Portz Brandschutz, Fellbach

Hell Ingenieure GbR, Ingelfingen

BFI Zeiser GmbH & Co. KG, Ellwangen

Rw-Bauphysik Ingenieurgesellschaft mbH & Co. KG, Schwäbisch Hall

Schlosser Holzbau GmbH, Jagstzell

Pollmeier Massivholz GmbH & Co. KG, Amt Creuzberg

Client

SWG Schraubenwerk Gaisbach GmbH, Waldenburg

Location

Kupferzell / Westemach

Completition

2020

Project Facts

n.b.ar. 14.195 m², GFA 14.798,66 m²,

GBV 128.462,06 m³

Rights

Text Tina Mott

Translation Bronwen Rolls

Photo Marc Lins

Text SWG Schraubenwerk, Gaisbach

Photo Arch. DI Roland Wehinger

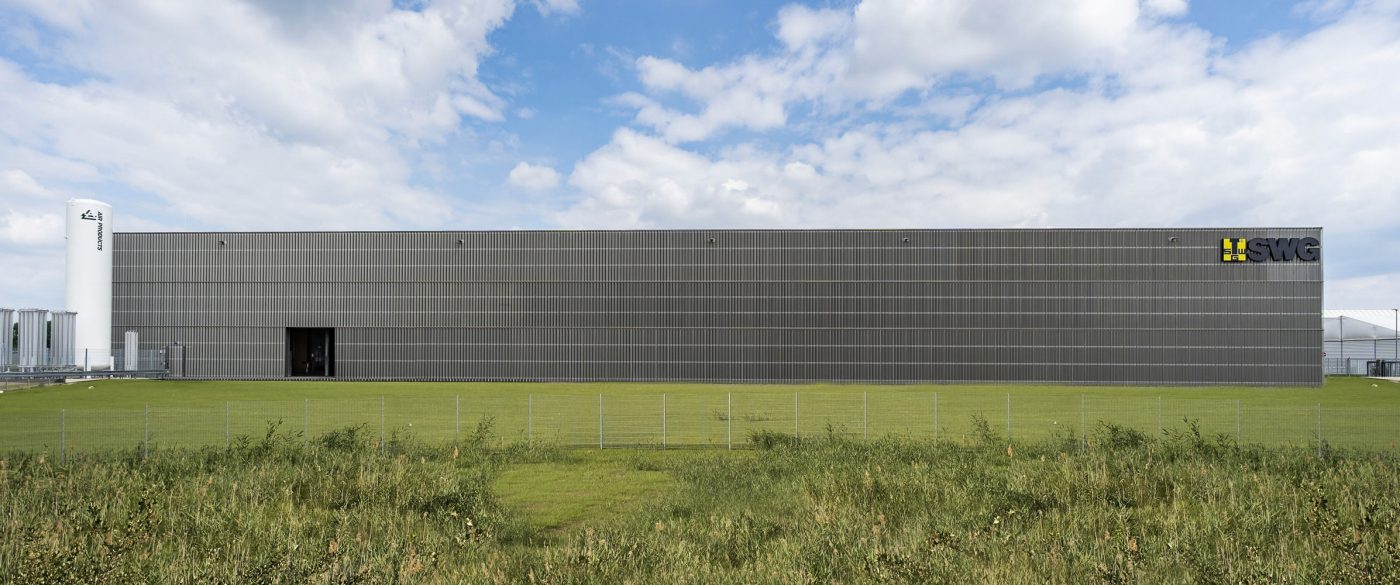

SWG screw factory Gaisbach GmbH, Waldenburg

The firm SWG owns a screw factory, 230 employees produce up to 12 million screws a day, and the demand is rising. In response to a necessary expansion the idea initially was to develop the existing company headquarters with an extension. The design team led by Prof. Hermann Kaufmann and his partners argued emphatically for the realisation of an autonomous new building in order to avoid disruptions to ongoing operations and problematic connections and transitions. In addition, a confident architectural appearance strengthens both public perception and the company’s self-image.

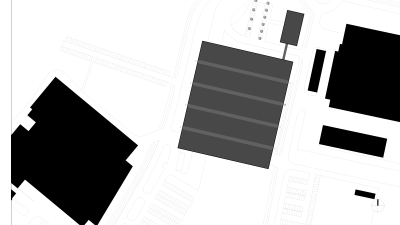

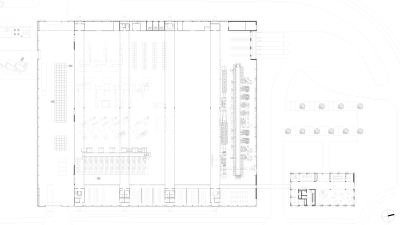

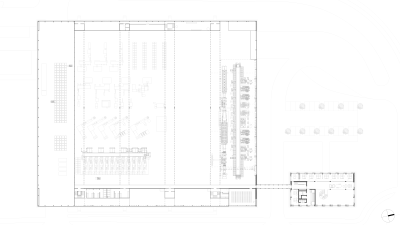

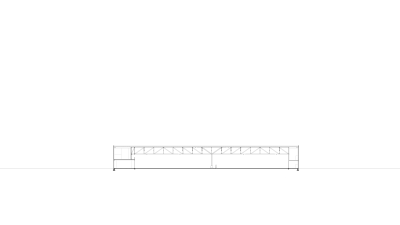

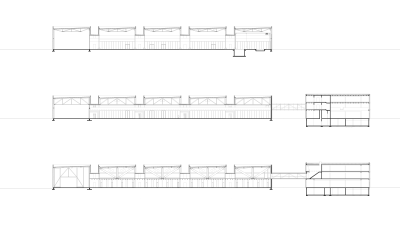

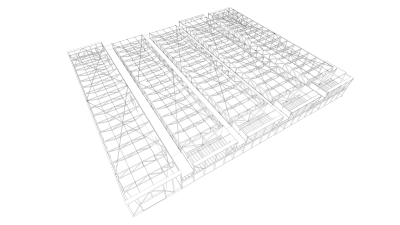

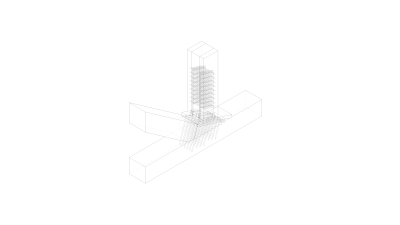

A building ensemble is now designed in the immediate vicinity of the company headquarters. The large-scale production hall is connected by a bridge to a three-storey pavilion, which, in addition to office space and meeting rooms, also includes an extensive reception and exhibition area for visitors. Here, interested parties can get to know the products and their applications and study the structure on site using the multiple illustrative examples. This places grater emphasis on the exacting quality of the construction and execution of the industrial building. The production facility has enormous dimensions to accommodate numerous large machines with extensive technical infrastructure. It extends over a length of 114 m and a width of 96.5 m, the height is about 12 m. 70% of the floor space is taken up by the manufacturing and logistics area, while 20% is earmarked for tools and tool making and a further 10% for the storage of raw materials.

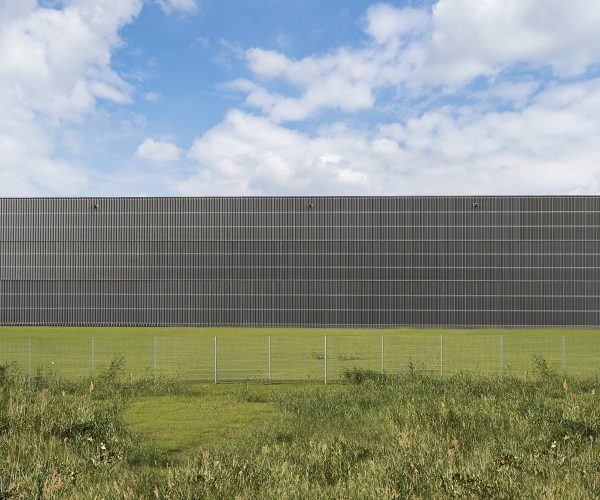

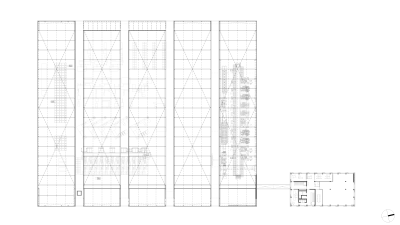

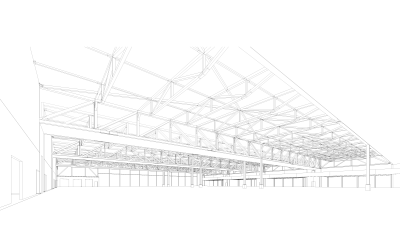

The building has five aisles and is spanned by a comb-like roof structure. Glazed recesses about 5 m wide between each section work like inverted sheds and create generous daylight exposure. A wire store has been set up towards the south, which is why the production area has to be separated by a fire wall. In the east and west, two narrow spaces encompass the volume they contain infrastructure facilities, workshops and areas for building services. In order to ensure a high degree of flexibility in the production processes, the number of supports in the hall is reduced to a minimum. The supporting structure consists of eight parallel, lengthways, 82 m long and 3.8 m high main truss girders and a row of 18.30 m long secondary truss girders that are hung transversely between them. Since the main trusses rest on only one intermediate support, they function statically as continuous girders with bay widths of 40 m or 42 m.

Corporate identity plays an important role in the choice of building materials. The SWG’s field of expertise is the production of screws for timber and mental construction. To reflect this the architects developed the concept of constructing the load-bearing structure of the hall in timber, while metal elements were used to design the facades. The conscious decision to use renewable building materials also sends out a signal for sustainability, because every cubic meter of “built-in” timber binds the carbon from 1 ton of CO2 from the atmosphere in the long term. In addition, other materials are replaced that would release CO2 again during their manufacture. Since a total of around 1,800 m³ of timber is used for the project, this means a CO2 saving of around 3,600 tons compared to conventional construction methods, based on a useful life of 50 years.

However, technical and economic arguments also speak in favour of a timber design. Made of steel or reinforced concrete, the individual components would have been too big, too heavy and in some cases not manufacturable and therefore the values required for fire protection would have proven problematic. In addition, the choice of a lighter building material means that no complex foundations are required on ground that is only partially stable, which means that the costs for the foundation work remain manageable. However, since coniferous timber is also out of the question due to the enormous cross-sections required, the architects and the in-house engineering team SWG Engineering looked at alternatives. The goal was to develop a truss structure as delicate as possible, the rods and components of which can be connected to one another by efficient nodes. Finally the material BauBuche GL75 was chosen, which is manufactured in Germany. This is a veneer made of regional hardwood, in which 4 mm thick lamellas are glued parallel to the fibres and thus achieve an extraordinarily high level of strength and rigidity. The flexural, compressive and tensile strength of the material is around three times that of conventional glued laminated timber.

Thanks to the high resistance to lateral pressure, very effective carpenter-like joints can be made. In addition, the high density of the material favours joints with pin-shaped fasteners, screws in particular. When using BauBuche you can achieve full load-bearing capacity even with short screw-in lengths. Through precise and courageous planning in conjunction with an innovative material, it was possible to implement a wide-span roof structure in timber, the construction elements of which are exceptionally slim, delicate and light.

Thanks to the compact and powerful joints, up to 100% of the cross-sections can be used, which means that the amount of timber required can be reduced to a minimum, saving resources. The world’s largest roof structure made of BauBuche demonstrates the scale which contemporary timber engineering can now go to. It was never possible to build to these dimensions before.

Project Plans

Baufotos

Public

- Hohenlohe-Tauberfranken

2023 (Award) - Holzbaupreis Baden-Württemberg

2022 (award) - Deutscher Holzbaupreis

2021 (credit award) - HolzbauPlus

2020 (credit award)