Project Information

Acton Ostry Architects Inc, Vancouver

DI Christoph Dünser

ARB Arch Matt Wood (AOA), Vancouver

DI Stefan Hiebeler

Urban One Builders, Vancouver

Urban One Builders, Vancouver

UBC Properties Trust, Vancouver

Client

The University of British Columbia

Location

Vancouver

Completition

2017

Project Facts

Land area 2727 m²

Floor area 15115 m²

Building surface 840 m

Energy

13,5 kWh/m²a

Certification

LEED Silber

Rights

Text Marko Sauer

Translation Bronwen Rolls

Photo Michael Elkan, Credit Acton Ostry Architects & University of British Columbia

- Structural Engineering

Fast + Epp, Vancouver - Heating Ventilation and Sanitary Planning

Stantec, Vancouver - Electronics Planning

Stantec, Vancouver - Fire Protection Planning

GHL Consultants Ldt., Vancouver - Building Physics

RDH Building Science Inc., Vancouver - Akustik

RWDI, Vancouver - Landscape Planning

Hapa Collaborative, Vancouver - Ausführender Holzbaubetrieb

Seagate Mass Timber, Surrey

Brock Commons Tallwood House, Vancouver

The University of British Columbia creates an ambitious skyscraper, taking timber construction to new heights. The Brock Commons dormitory in Vancouver, Canada designed for 400 students is the tallest mass timber building in the world when complete, standing at 53 meters high. For the university it is their eighth large scale timber construction, and for the timber industry of the region this type of production brings a boost of new innovation. Architekten Hermann Kaufmann GmbH joined the construction project as “TallWood Advisors” and contributed their experience and expertise in efficient timber construction.

»This remarkable building, the first of its kind in the world, is another shining example of Canadian ingenuity and innovation, an apt demonstration of how Canada’s forest industry is finding new opportunities through technology and innovation.«

Jim Carr, Canada’s Minister of Natural Resources

The timber industry dominates in British Columbia. The wooded province in western Canada exports wood products worth around € 10 billion each year. Not surprisingly, the building material in the region has a long tradition, but what is astonishing is the low level of innovation in modern timber construction in Canada. Conventional constructions methods dominate. Small scale buildings still utilise a balloon-frame design, and even for larger buildings, the structure usually consists of a conventional frame construction. With massive construction and modular prefabrication, the local construction industry is relatively inexperienced.

According to the website naturallywood.com the wood industry in British Columbia sees enormous potential in solid timber structures. The structural properties are comparable to a steel or reinforced concrete construction, but they clearly are superior to more traditional construction materials in terms of sustainability and construction time. In particular, large buildings can be efficiently and economically produced in wood.

The 18-storey timber construction in the Brock Commons campus demonstrates the efficiency of the building material with around 15,000 m2 of floor space. In 2009, local authorities increased the maximum number of storeys from four to six in order to increase the height of wooden buildings. For the 53 m high dorm this change was not enough. However, the campus has its own building regulations and the Canadian building laws allow for exceptions. This made it possible to use timber to create these new dimensions, but the requirements for earthquake safety and fire safety were more stringent than for a steel or reinforced concrete construction.

The approval process was time-consuming: in addition to a peer review, a committee of fire protection experts, scientists, authorities and firefighters assessed the construction. To increase the resistance of the wooden structure against fire, the wooden components are packed in plasterboard. Only on the top floor, which serves as a recreation room for the students, the timber is visible and provides a window into the construction method used to create the skyscraper. A redundant system supplies the sprinkler system with water and electricity even if the connections to the public network are interrupted.

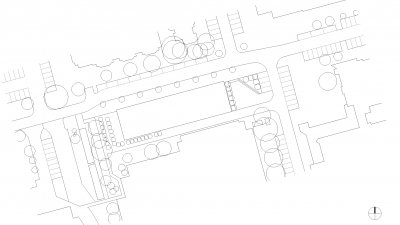

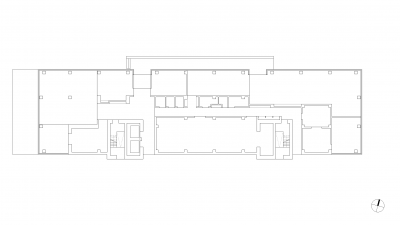

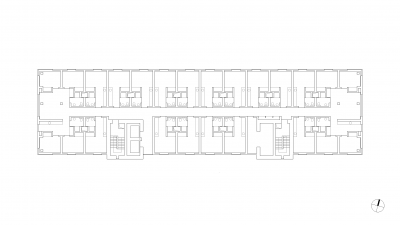

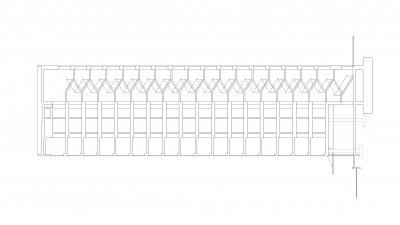

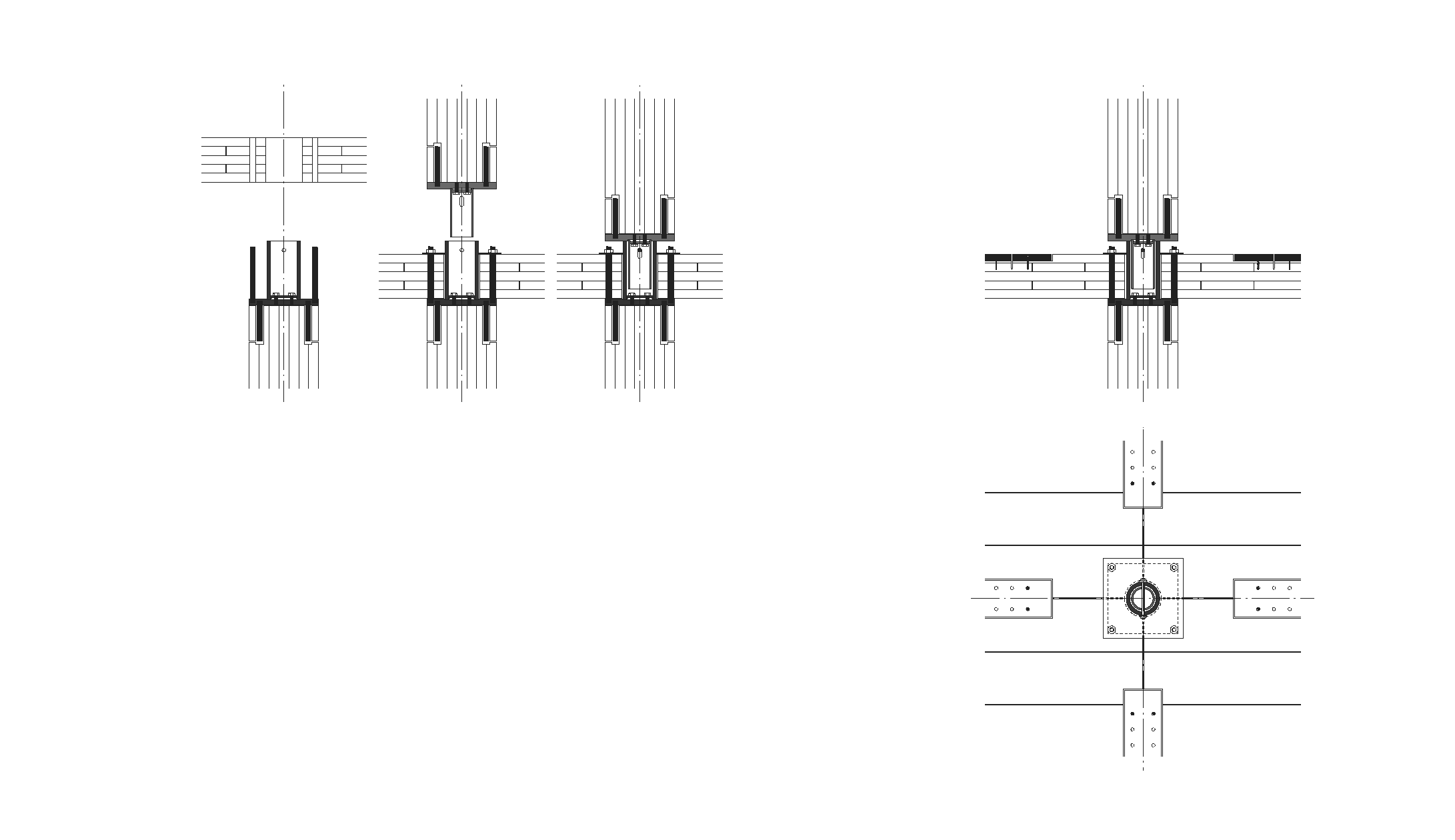

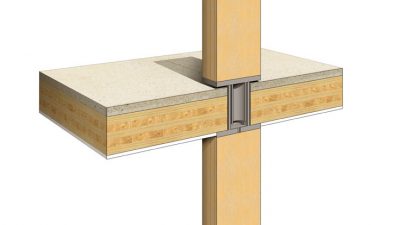

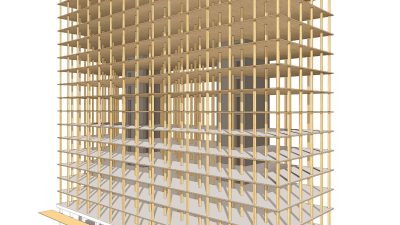

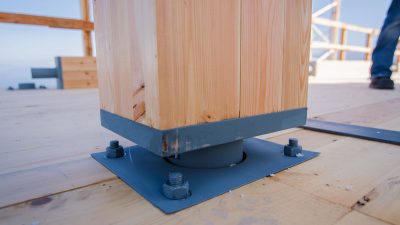

The supports of the modular timber construction consist of laminated beams that are 26 x2 6 cm. They are arranged on a floor plan of 15 x 56 m, in a grid of 2.85 x 4 m. On the columns lie ceiling slabs of cross-laminated timber (CLT), the five layers of theses slabs create a total thickness of 16.6 cm. The staggered two- and three-field plates are biaxially stretched, thus enabling a ceiling completely without joists. In addition to a quick installation, this has the advantage that the technical building equipment can be easily installed. The shear bond between the individual CLT plates is produced with a recessed 3-layer plate. This creates a statically usable disk out of the individual plates. All horizontal forces (wind, earthquakes) are transmitted via steel bands from this disc into the concrete tower. The wooden supports take away the vertical loads and pass them on to a reinforced concrete structure on the ground floor. The building was built within a very short time. Every week, the construction grew by two floors; the total build took only 9 and half weeks and was completed ahead of schedule.

The building’s expression adopts the sober and modernist language of the entire campus. The façades are made of Canadian standard steel frame construction, with a panel of high-pressure wood and paper laminate panels, with alternating large Trespa panels and floor-to-ceiling windows. Corner glazing dissolves the volume of the surfaces and a metal cornice crowns the building. A sunshade, made of CLT, adds the warm atmosphere of the outside common areas. The vestibules of the elevators are clad in the same way as the facades in the student housing area. The corridors feature wooden doors and colour accents in umber and ochre. The interior of the 305 studios, and four larger units, are economical and simple: the warm colours of the carpets compliment the white gloss surface of the desks. The view of the ocean and the mountains is spectacular.

In addition to the transfer of industrial know-how, ambitious sustainability goals are being pursued. The LEED Gold label is being achieved and the standard ASHRAE 90.1-2010 (Energy Standard for Buildings Except Low-Rise Residential Buildings) must be fulfilled. Compared to a conventionally constructed building, the new dormitory saves 25% of grey energy and consumption from the operation. The building owner has already made an important contribution to the protection of the environment with the choice of construction material: the solid wood construction saves a volume of 2,650 m³ of concrete, which corresponds to an equivalent of around 500 tonnes of CO2.

The dormitory is an important pilot project for solid construction in wood. In order to make the ecological qualities of this type of construction a relevant factor, however, it has to be used in a wide variety of scales and uses – both in visible applications and in timber construction. To promote this construction, the project was funded by the TallWood Buildings Demonstration Project Initiative, with contributions from the Province of British Columbia, the Binational Softwood Lumber Council and FP Innovations.

Project Plans

Baufotos

Public

- Austrian Green Planet Building Award

2022 (Award) - Holzbaupreis Vorarlberg

2019 (Anerkennung) - International Prize for Wood Architecture

2018 - Architectural Institute of British Columbia

2018 (Award) - Sustainable Architecture & Building

2018 (Green Award) - Canadian Wood Council Wood Works

2018 (Architect Award) - Canadian Wood Council Wood Works

2018 (Innovation Award) - Canadian Wood Council Wood Works

2018 (Engineer Award) - Council on Tall Buildings and Urban Habitat Award

2018 (Finalist) - Vancouver Regional Construction Association Award

2018 (Award) - Lieutenant Governor of BC Engineering Excellence Award

2018 ( Award) - Fast Company Innovation by Design

2017 (Finalist) - Construction Dive Five

2017 (Favourite Projects of the Year) - Premier’s Innovation & Excellence Award

2017 (Award) - NCSEA Excellence in Structural Engineering Award

2017 (Award) - Institution of Structural Engineers Innovation Award

2017 (Award) - Canadian Wood Council

2017 (Special Jury Award) - Wood Design & Building 2017

2017 (Auzeichnung - Technische Innovation)

- Austrian Green Planet Building Award 2022

- Baunetz_Wissen Brock Commons Tallwood House in Vancouver

- canadian consukting engineer- Magazine for professional engineers in construction

- ReNew Canada - 18-Storey UBC Residence to Be Among Tallest Wood Buildings

- Vancity Buzz - 18-storey UBC wooden tower to be one of the tallest of its kind in the world

- Business in Vancouver - UBC plans 18-storey wood building

- University of British Columbia - news

- UBC Flickr Album

- Canadian Wood Council - broschure

- Matterport terms - virtual tour

- Future of Structures - podcast

- Baunetz_Wissen Brock Commons Tallwood House in Vancouver

- Vancouver Courier - UBC plans 18-storey wood building

- Time Columnist - UBC approves 18-storey residential tower made of wood

- Vancouver Sun - UBC to build 18-storey student residence out of wood

- Journal of Commerce - UBC planning one of the world’s tallest wood towers

- Official UBC press release link

- Journal of Commerce - Cost is biggest challenge for UBC wood project

- The Vancouver Sun - Wood symposium tackles tall timber tower construction

- pro:Holz - UBC Brock Commons

- german-architects -Groß in Holz

- archdaily -Inside Vancouver's Brock Commons, the World's Tallest Mass Timber Building

- thinkwood -Demonstrating the viability of mass wood structures

- The Skyscraper Center - Brock Commons Tallwood House

- seagate mass timber - UBC Brock Commons

- Atlas Obscura - Brock Commons Tallwood House

- Canadian Architect - Standing Tall

- holzbauaustria - WELTREKORD: 18 Geschosse in drei Monaten

- wood innovates bc - Explore Brock Commons Tallwood House

- make wealth history - Building of the week: Brock Commons Tallwood House

- cyberarchi - La Brock Commons Tallwood House, University of British Columbia, Vancouver

- treehugger - Tall wood gets green light from building code

- BUILDING - Canada Wood Council publishes Brock Commons case study