A mountain lodge located at 2400 meters constructed from 350 prefabricated timber parts, delivered by helicopter and erected in three days.

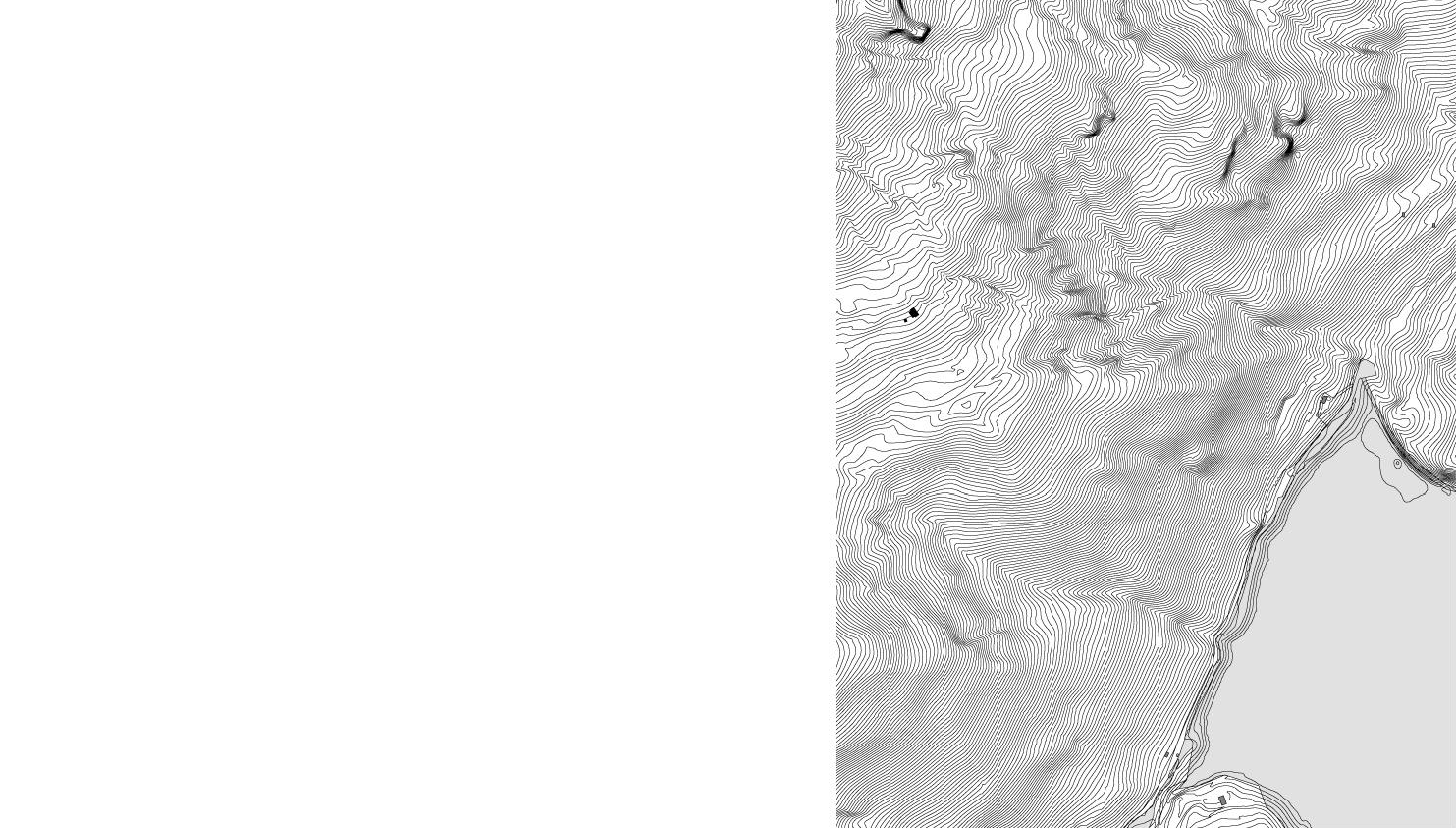

For more than a hundred years a shelter had been standing at this exposed location high above the “Schlegeisspeicher” reservoir, opposite it the glaciers and the mountain tops of the Zillertal Alps. Since refurbishment of the old building was impossible, in 2005 the decision was made to build a new one. Our company principle of “innovation through reduction” is never more so reflected, than in this project.

Construction at great heights did, and still does, depend on the availability of transportation. The old hut was made of stones from the surrounding area. The transport of large quantities of construction material from the valley was not feasible in those days and the labour-intensive stone masonry was cheaper. Modern means of transportation, such as helicopters, have changed things. Prefabricated construction materials, together with the new possibilities provided by glue-laminated timber, allow for easy transport and furthermore they can be quickly assembled, which is an important aspect in high altitude construction. In addition, the physical qualities of timber allow for direct and optimal ecological construction. The glue-laminated timber panels have both load-bearing and insulation properties. Extra insulation, because the hut is only open in the summer, was not required. This pure timber structure without insulation materials, cladding etc. can, plainly speaking, just rot up there. Due to the harsh weather conditions, the shingled outer surfaces in a few years with weather and the timber will have entered into dialog with the surrounding world of stone.

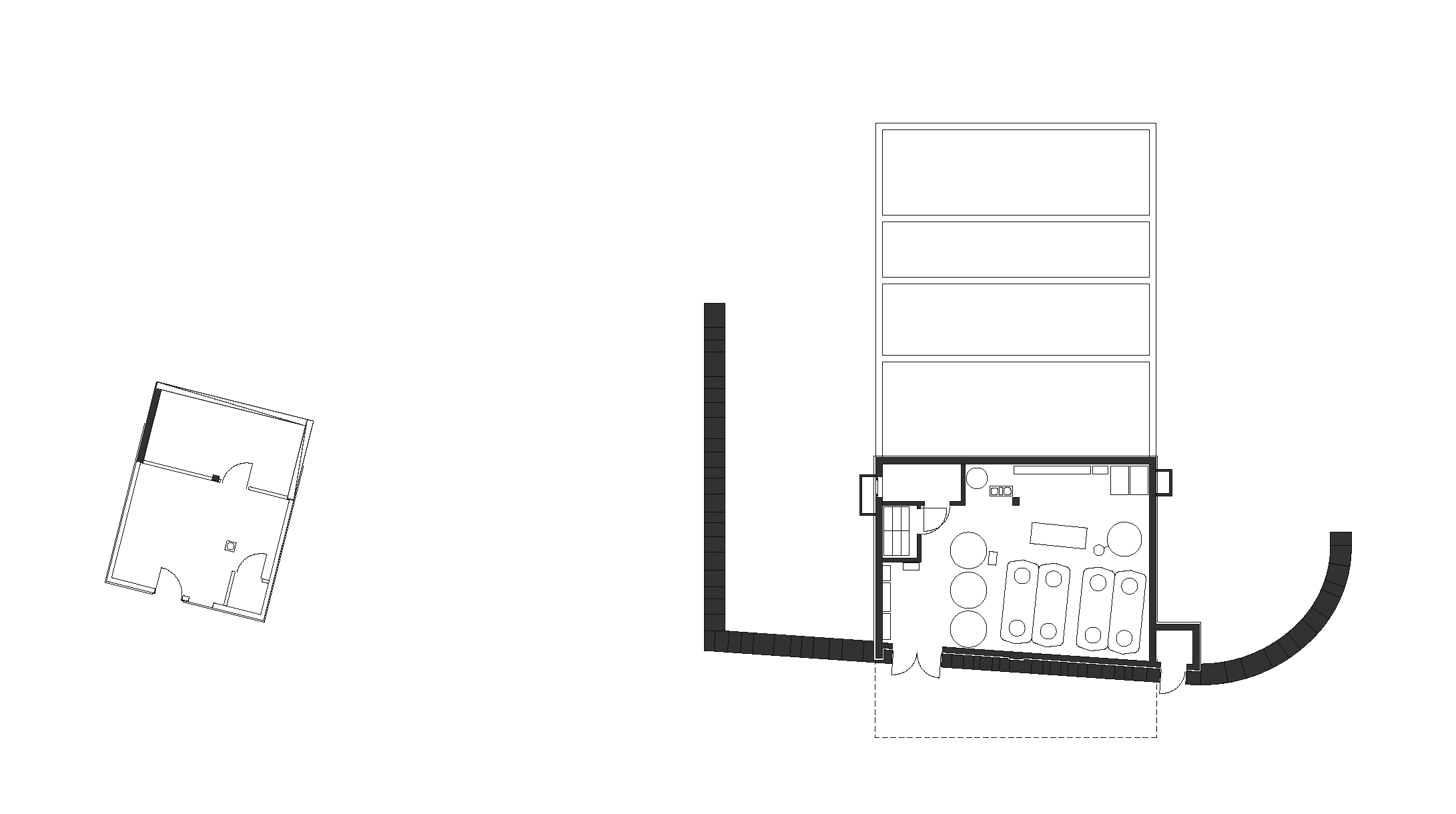

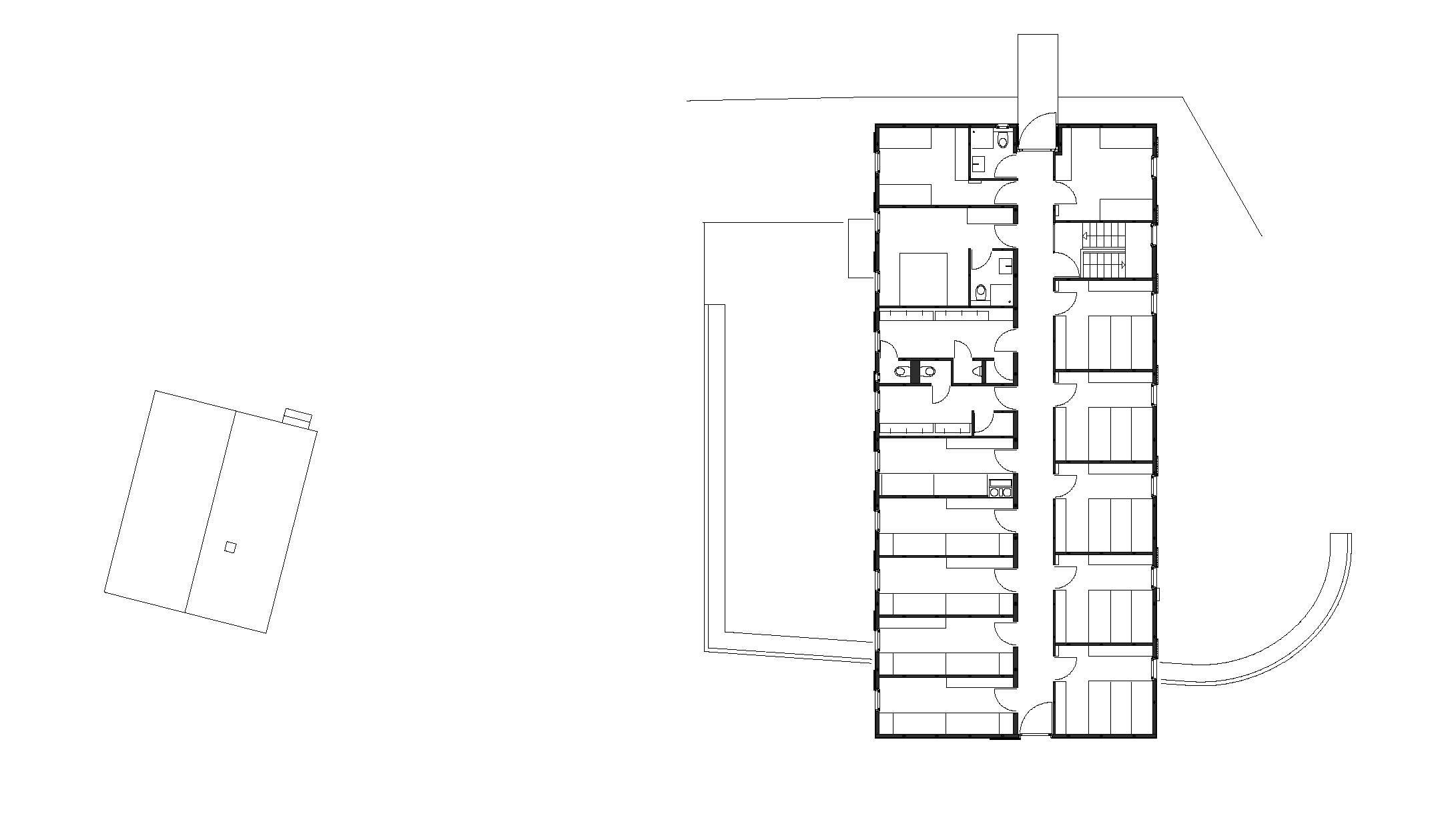

The hut has been deliberately been designed as a refuge and not as a hotel. It is a summer hut; the comfort is equal to the expectations for such a location. The entrance and bedrooms are unheated. The building utilities are limited to a minimum. A tiled stove and the waste heat of the photovoltaic and canola oil powered CHP used for water purification; both supply the building with heat.

Read more

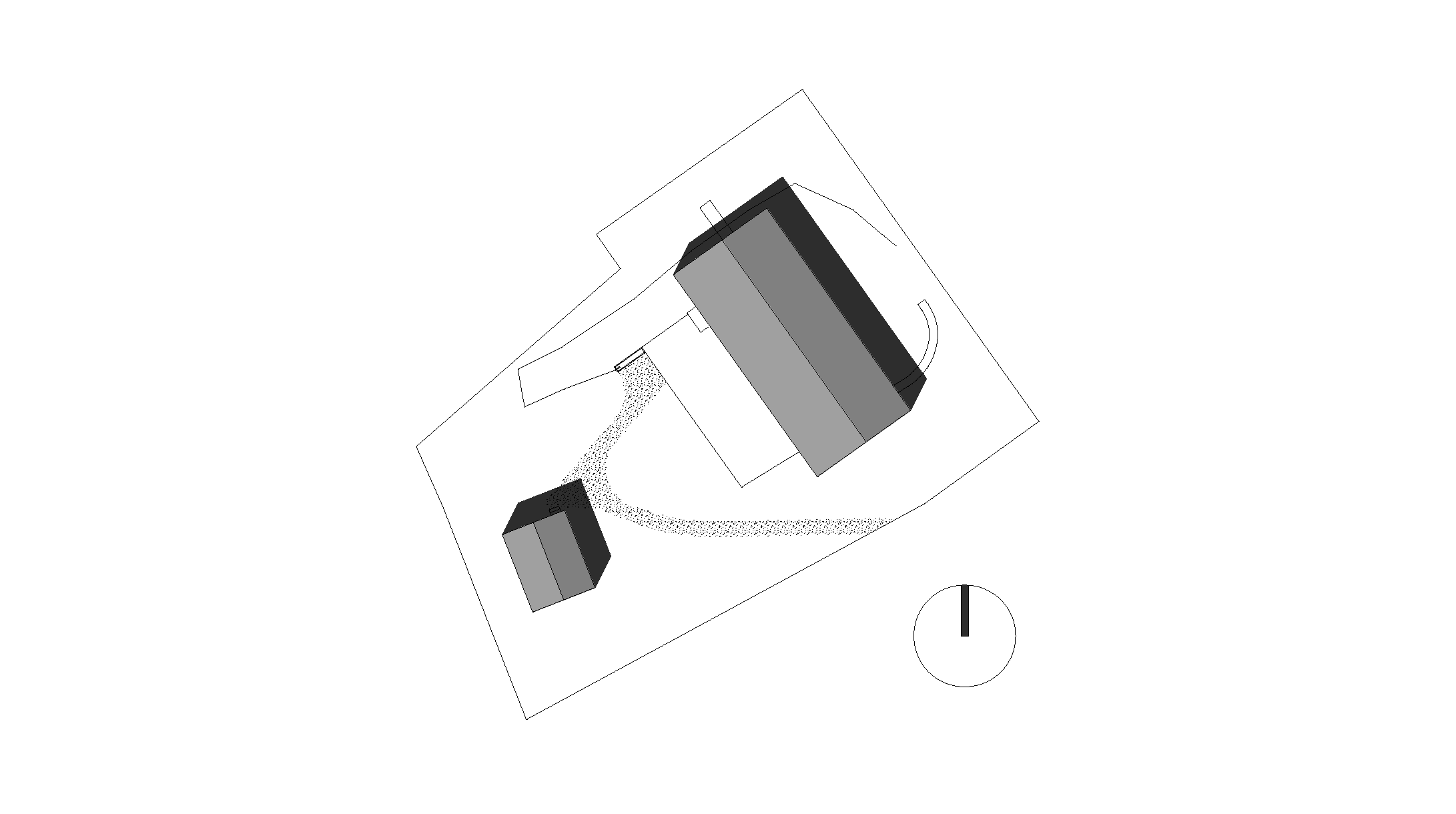

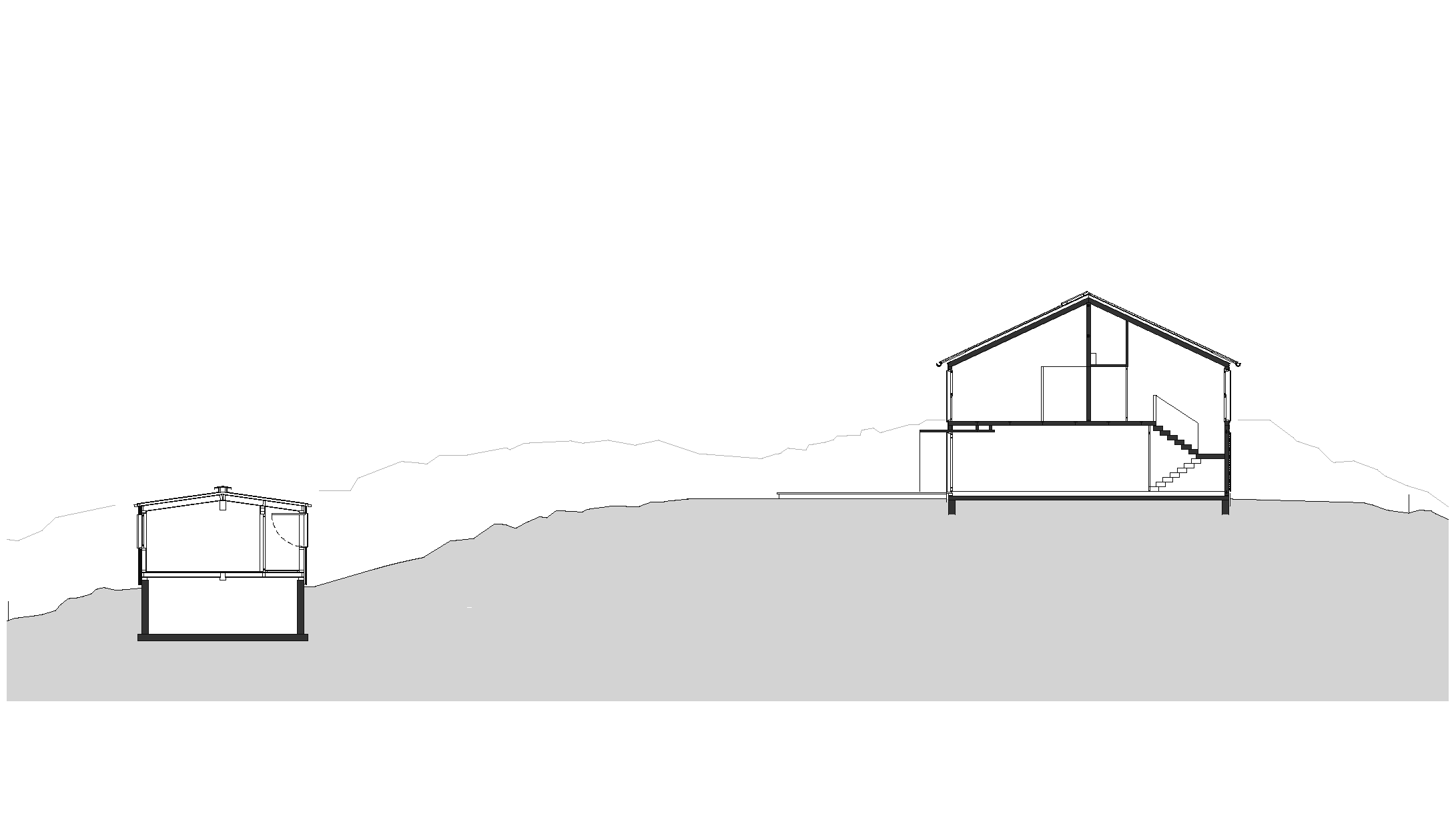

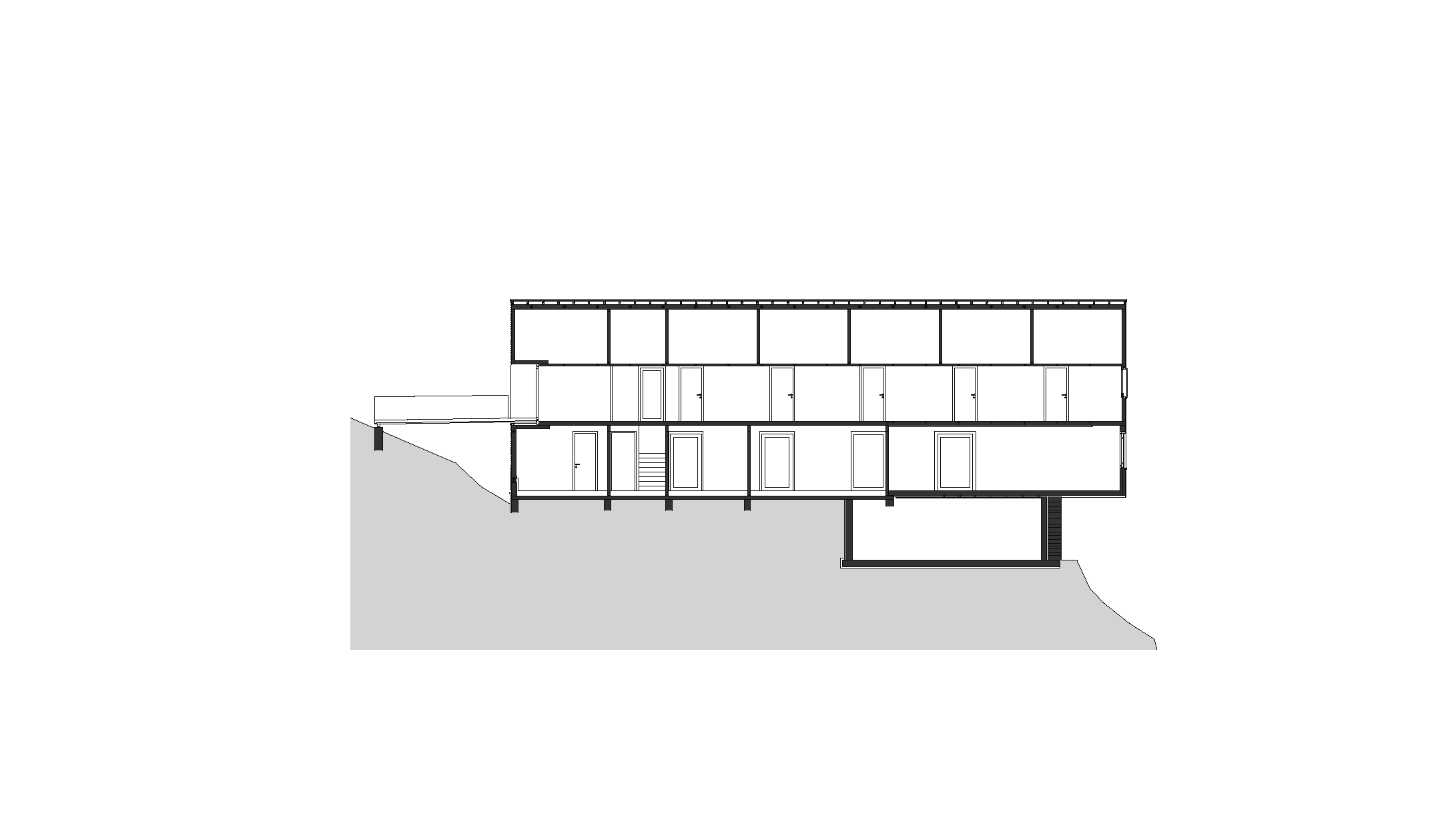

The motto of “innovation through reduction” is reflected in the typo-logical approach. A compact structure with a pitched roof, cantilevered over a retaining wall towards the reservoir, has replaced the old building. The concrete base, which has been clad with stone from the surrounding area, has been back filled with rubble from the demolition, the house itself consists of glue-laminated spruce timber. The outer walls of the ground floor act as support plates and are, in order to reduce the load on the cantilever, hinge jointed to the base. Mounted to these cantilevers is the large-format picture-window on the gable wall. Suspended from this is the floor plate of the restaurant. The bracing is provided by the floor plate and by the roof, which also acts as a foundation. A small, thermally insulated auxiliary building serves as winter shelter and accommodation for self-catering visitors.