Project Information

DI Ingo Gehrer, Höchst

merz kaufmann partner GmbH, Dornbirn

Client

Kaufmann Holz AG

Location

Reuthe

Completition

1992

Project Facts

n.b.ar. 9.700,00 m²

Projektphasen

Hall Au

Assembly Hall

Rights

Text Hermann Kaufmann + Partner ZT GmbH,

Translation Bronwen Rolls

Photo Ignacio Martinez

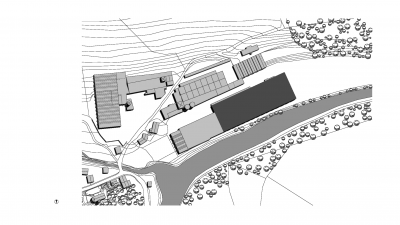

Kaufmann Holz AG – Factory Hall Au, Reuthe

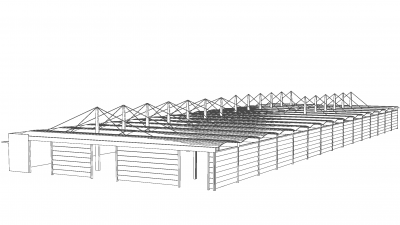

On 19 August 1992 a major fire at Kaufmann Holzbauwerk, in Reuthe, destroyed a 7,000 m2 hall with facilities for drying and sorting of timber, as well as 7,000 m³ of dry and processed stock. It was paramount to quickly turn around a new hall and a warehouse for all sorting and drying of timber, for the company to get back to business.

For planning and building permits 4 weeks where scheduled for the construction of 10,000 m², building, an estimated 2 months. Therefore the design of the hall is based on a very easy to assemble and build concept. The new building material Intrallam LSL, which is manufactured in large-sized panels, was the most suitable product for this purpose. The large format allows a high degree of prefabrication and thanks to the high strength qualities this plate could be used not only as a space-enclosing element, but also as a support. During the foundation work, the prefabrication of the roof and wall elements in the timber framed hall was carried out in shifts. After erecting the first two main trusses, they immediately went on to lay the roof elements and weld the sealing foils. This continuous development process of the construction also includes the lengthwise wall made of timber. After seven weeks of construction the hall could be used again in time for Christmas.

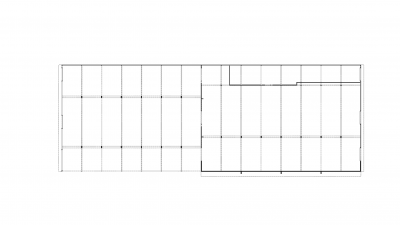

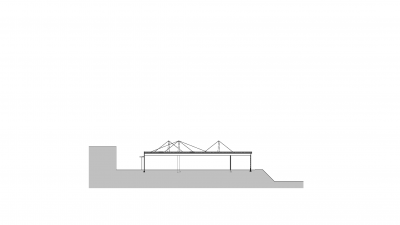

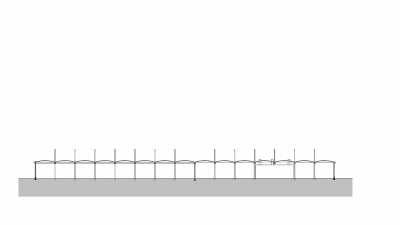

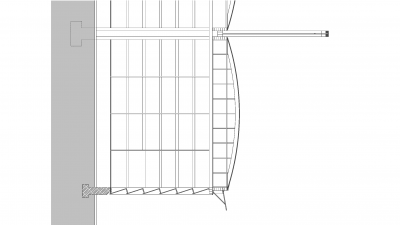

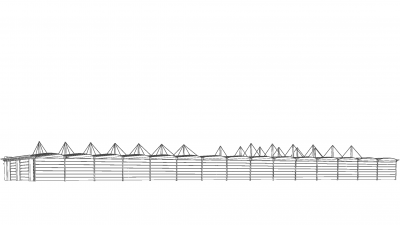

The building is divided into two sections with different widths. The pylons consist of 2 HEA profiles each, with diagonals connected to a grid support. All other supports are made of timber, with Parallam, glued laminated timber or a cross-section composed of these materials, depending on the load and constructional considerations.

The two BSH twin carriers act as a continuous beam, while the intermediate Parallam sections compensate for the horizontal pressure component of the bracing and form the substructure for the drainage channel. The secondary carrying system was made of the large-sized Intrallam plates which are bent and connected with curved glued ribs. Together with the steel tie rods, the ribbed panels act like a double hinged arch. The load of 380 kg /m2 required the use of 40 mm thick plates and 3 ribs per plate. Two anchor steels were used under tension. The walls were also folded large Intrallam panels and transfer both load baring weight and wind forces to the main columns of the building. The design of this hall was carried out within a planning team involving engineers, builders and architects. This interdisciplinary process was necessary for planning efficiency.

Project Plans

Public

- Holzbauwerk Kaufmann

ZN B-013, architektur & wirtschaft, Journal internat. Bodenseeregion, S. 30-31 - Holzlager und Abbundhalle

ZN B-003, Sommer / Weißer / Holletschek, Architektur für die Arbeitswelt, S. 96-99 - Industriebau – ein Thema?

ZN B-003, Sommer / Weißer / Holletschek, Architektur für die Arbeitswelt, S. 21-22 - Lagerhalle Holzbauwerk Kaufmann

ZN B-035, Neues Bauen in den Alpen, Architekturpreis 1995, S. 52-57 - Holzrahmenbau und Rippendecken

ZN B-010, Landsberg / Pinkau, Holzsysteme für den Hochbau, S. 198-199, S. 144-145 - Purismus made in Austria

ZN Z-014, Architektur & Wohnen, 3/2001, S. 163-164 - Jedinecne krabice z Vorarlbergu

ZN Z-031, ARCH o architektúre a inej kultúre , marec 2001, S. 16-18 - Ein roter Faden aus Holz

ZN Z-078, Ryll Christine, Deutsche Bauzeitschrift 10/2001 S. 127 - Holz – ein universeller Baustoff

ZN Z-108, Hermann Kaufmann, Detail, Bauen mit Holz 1/2 2004, S.14 - Langspanholz

ZN B-027, Ambrozy / Giertlova, Planungshandbuch Holzwerkstoffe, S. 206-209- - Kaufmann Holz – AG Warehouse

ZN Z-118, World Architecture, 8/2005, S. 45-47 - Industrie- und Gewerbebau in Holz

ZN Z-132, Kaufmann Hermann, Informationsdienst Holz, 2007